Tus tsiaj

Polyethylene terephthalate siv (qee zaum sau poly (ethylene terephthalate)), feem ntau hais luv Tus tsiaj, HOM, lossis PETP lossis PET-P, uas tsis tshua muaj neeg, yog cov neeg feem ntau thermoplastic polymer cob ntawm lub polyester tsev neeg thiab yog siv nyob rau hauv fibers rau khaub ncaws, ntim rau cov kua thiab cov khoom noj, cov thermoforming rau kev tsim khoom, thiab muaj kev sib xyaw nrog cov iav fiber rau engineering resins.

Nws tseem tseem yuav raug xa mus rau lub npe hom Dacron; hauv tebchaws Aas Kiv, Terylene; los yog, nyob Xos Viav thiab teb chaws Xiv Naus Qub, Lavsan.

Feem ntau ntawm lub ntiaj teb cov PET ntau lawm yog rau cov hluavtaws hluavtaws (ntau dua 60%), nrog kev tsim khoom hauv lub raj mis txog li 30% ntawm cov neeg ntiaj teb xav tau. Hauv cov ntsiab lus ntawm textile applications, PET raug xa mus rau los ntawm nws lub npe, polyester, whereas lub acronym Tus tsiaj feem ntau siv in relation to ntim. Polyester ua tau txog 18% ntawm ntiaj teb polymer ntau lawm thiab yog plaub-feem ntau-tsim polymer; polyethylene(PE), polypropylene (PP) thiab polyvinyl tshuaj dawb (PVC) yog thawj, thib ob thiab peb, feem.

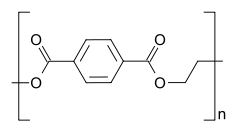

TSIAJ muaj polymerized chav nyob ntawm monomer ethylene terephthalate, nrog rov ua dua (C10H8O4) units. PET yog feem ntau ua dua tshiab, thiab muaj tus lej xov tooj 1 raws li nws cov cim kev ua lag luam.

Raws li nws ua thiab keeb kwm thermal, polyethylene terephthalate yuav muaj nyob ob qho tib si li amorphous (pob tshab) thiab raws li Semi-crystalline polymerCov. Cov khoom siv ua semicrystalline yuav tshwm tuaj pob tshab (qhov loj me <500 nm) lossis opaque thiab dawb (qhov loj me txog ob peb micrometers) nyob ntawm nws cov qauv siv lead ua thiab qhov loj me. Nws cov monomer bis (2-hydroxyethyl) terephthalate yuav muab tsim los ntawm tus esterification cov tshuaj tiv thaiv ntawm terephthalic kua qaub thiab ethylene glycol hmoov nrog dej raws li kev ua, los ntawm transesterification cov tshuaj tiv thaiv ntawm ethylene glycol hmoov thiab Dimethyl terephthalate hmoov nrog methanol raws li lub chaw ua haujlwm. Polymerization yog los ntawm a polycondensation cov tshuaj tiv thaiv ntawm cov monomers (ua tam sim ntawd tom qab esterification / transesterification) nrog dej raws li kev ua.

| npe | |

|---|---|

| IUPAC npe

Poly (ethyl benzene-1,4-dicarboxylate)

|

|

| Cov ntsiab lus | |

| 25038-59-9 |

|

| abbreviations | TSIAJ, PIAV |

| Properties | |

| (C10H8O4)n | |

| Molar loj | kuj sib txawv thiab |

| ceev | 1.38 g / cm3 (20 ° C), amorphous: 1.370 g / cm3, ib leeg siv lead ua: 1.455 g / cm3 |

| melting point | > 250 ° C, 260 ° C |

| ib kub npau npau taw tes | > 350 ° C (decomposes) |

| insoluble | |

| Thermal conductivity | 0.15 txog 0.24 W m-1 K-1 |

|

Refractive index(nD)

|

1.57–1.58, 1.5750 |

| Thermochemistry | |

| 1.0 kJ / (kg · K) | |

| Yam sib txuas | |

|

Related Cov Monomers

|

Terephthalic acid Ethylene glycol hmoov |

|

Dhau ntawm qhov tsis muaj sau tseg, cov ntaub ntawv tau muab rau cov ntaub ntawv hauv lawv txheem xeev (ntawm 25 ° C [77 ° F], 100 kPa).

|

|

siv

Vim tias PET yog cov dej muaj txiaj ntsig zoo tshaj plaws thiab cov khoom tiv thaiv noo, cov yas hwj tau ua los ntawm PET yog dav siv rau cov dej haus (saib cov pa roj carbon monoxide). Rau qee qhov tshwj xeeb hauv lub raj mis, xws li cov uas tsim los rau cov ntim npias, PET cov qhaub cij tau ntxiv cov polyvinyl cawv ntxiv (PVOH) txheej ntxiv los txo nws cov pa permeability.

Biaxially oriented tus tsiaj zaj duab xis (feem ntau paub los ntawm ib qho ntawm nws cov npe lag luam, "Mylar") tuaj yeem aluminized los ntawm evaporating nyias zaj duab xis ntawm hlau mus rau nws kom txo tau nws cov permeability, thiab ua kom nws muaj kev cuam tshuam thiab tsis zoo (MPET)). Cov khoom no muaj txiaj ntsig hauv ntau daim ntawv thov, suav nrog cov zaub mov hloov tau yooj yim ntim thiab thermal rwb thaiv tsevCov. Saib: “chaw pam vov“. Vim tias nws lub zog siab los siv zog, PET zaj duab xis feem ntau siv rau hauv cov kab xev, xws li cov cab kuj rau cov ntaub nplaum los yog thim rov qab rau cov yeeb yaj kiab siab-nplaum nplaum.

Tsis-taw qhia txog cov tsiaj PET tuaj yeem yog thermoformed los ua cov ntim cov tais thiab cov hlwv pob. Yog siv cov nplai crystallizable PET, cov tais yuav siv rau cov chaw noj mov txias, vim tias lawv tiv taus ob qho txias thiab qhov cub ci. Raws li txwv ntawm amorphous PET, uas yog pob tshab, crystallizable PET lossis CPET feem ntau ua rau cov xim dub.

Thaum ntim nrog cov nplais iav lossis cov fibers, nws tiav niam txiv stiffer thiab ntau ruaj.

PET tseem yog siv los ua cov txheej txheem hauv cov zaj duab xis nyias nyias rau lub hnub ci.

Terylene tseem tau spliced rau hauv cov hlua khawm kom pab tiv thaiv kev hnav ntawm txoj hlua thaum lawv dhau ntawm lub qab nthab.

Keeb kwm

Tus tsiaj yog patent hauv xyoo 1941 los ntawm John Rex Whinfield, James Tennant Dickson thiab lawv tus tswv haujlwm ntawm Calico Printers 'Association ntawm Manchester, Askiv. EI DuPont de Nemours hauv Delaware, Tebchaws Asmeskas, thawj zaug siv lub cim kev lag luam Mylar thaum Lub Rau Hli 1951 thiab tau txais kev tso npe ntawm nws xyoo 1952. Nws tseem yog lub npe zoo tshaj plaws siv rau polyester zaj duab xis. Tus tswv tam sim no ntawm lub cim yog DuPont Teijin Films US, koom tes nrog cov tuam txhab Japanese.

Hauv Soviet Union, PET yog thawj zaug tsim hauv chav soj ntsuam ntawm lub koom haum ntawm Kev Sib Tw Siab Hauv Tebchaws ntawm USSR Academy ntawm Kev Tshawb Fawb hauv xyoo 1949, thiab nws lub npe "Lavsan" yog acronym thereof (laоратории Института всококомолекулярных сqhov chaw АKev hlub нib СССР СССР).

Tus tsiaj lub raj mis tau patented hauv 1973 los ntawm Nathaniel Wyeth.

Lub cev lub cev

PET nyob rau hauv nws lub xeev ntuj yog qhov tsis muaj kob, cov semi-crystalline yas. Raws li nws ua tiav li cas, PET tuaj yeem yog ib nrab txhav txhav, thiab nws hnav heev. Nws ua rau cov pa roj zoo heev thiab teeb meem noo noo zoo, nrog rau cov cawv zoo (yuav tsum muaj kev kho mob ntxiv) thiab cov kuab tshuaj. Nws muaj zog thiab cuam tshuam-tiv taus. Tus tsiaj ua dawb thaum muaj chloroform thiab tseem muaj lwm yam tshuaj lom neeg xws li toluene.

Txog 60% crystallization yog qhov txwv sab saud rau kev lag luam khoom lag luam, tsuas yog qhov tsis suav ntawm cov cheeb tsam polyester. Cov khoom ntshiab tuaj yeem tsim tawm los ntawm kev ua kom kub ceev molten polymer hauv qab Tg iav kev hloov pauv kub kom tsim ib qho khoom amorphous. Zoo li iav, amorphous PET cov ntaub ntawv thaum nws cov lwg me me tsis tau muab sijhawm txaus los npaj lawv tus kheej kom muaj txheej txheem, raws li crystalline zam raws li cov yaj tau txias. Nyob rau hauv chav tsev kub cov molecules tau khov rau hauv qhov chaw, tab sis, yog tias lub zog txaus rau cua sov tau muab tso rov qab rau hauv lawv los ntawm cua kub saum Tg, lawv pib tsiv mus nyob dua, cia cov muaju rau nucleate thiab loj hlob. Cov txheej txheem no raug hu ua crystallization solid-state.

Thaum tso cai kom txias qeeb, cov hlau molten daim ntawv ua cov khoom siv crystalline ntau dua. Cov khoom siv no muaj spherulites muaj ntau tus me me neeg muaju thaum crystallized los ntawm amorphous khoom, ntau dua li tsim ib qho loj loj siv lead ua ib qho. Lub teeb nyhav rau scatter thaum nws hla tus ciam ntawm crystallites thiab amorphous thaj tsam ntawm lawv. Qhov tawg duab no txhais tau hais tias PET crystalline yog opaque thiab dawb feem ntau. Daim duab fiber ntau yog ntawm qee cov txheej txheem kev lag luam uas tsim cov khoom lag luam ze li ntawm ib leeg.

Sab hauv viscosity

Ib qho ntawm cov cwj pwm tseem ceeb tshaj plaws ntawm PET raug xa mus rau intrinsic viscosity (IV).

Kev nkag siab viscosity ntawm cov khoom, pom los ntawm extrapolating rau xoom concentration ntawm tus txheeb ze viscosity rau cov concentration uas yog ntsuas hauv kev txiav txim siab ib gram (dℓ / g). Intrinsic viscosity yog nyob ntawm qhov ntev ntawm nws cov saw polymer tab sis tsis muaj cov khoom siv vim yog ua tau ntxiv rau xoom. Qhov ntev dua cov polymer txuas ntau cov khoom sib txawv ntawm cov saw thiab yog li ntawd lub siab dua cov viscosity. Txoj hlua nruab nrab ntev ntawm ib qho tshwj xeeb ntawm cov roj yuav tuaj yeem tswj tau thaum lub sijhawm polycondensation.

Tus kabmob viscosity ntau ntawm PET:

Qib fiber ntau

- 0.40-0.70 Textile

- 0.72–0.98 Kev tseb, log tsheb txoj siv sia

Zaj duab xis qib

- 0.60-0.70 Tub Npis (biaxially qhia cov tsiaj zaj duab xis)

- 0.70–1.00 Qib qib rau thermoforming

Lub raj mis qib

- 0.70–0.78 Cov fwj dej (ua ke)

- 0.78–0.85 Kev haus dej haus cawv qib

Monofilament, yam xws li tshuab yas

- 1.00-2.00

Kom qhuav

PET yog hygroscopic, txhais tau tias nws nqus tau dej los ntawm nws ib puag ncig. Txawm li cas los xij, thaum lub sijhawm "ntub dej" TSIAJ no tom qab ua kom sov, dej hydrolyzes PET, txo qis nws cov ua tsis taus. Yog li, ua ntej cov kua ntoo tuaj yeem ua tiav hauv cov tshuab moulding, nws yuav tsum tau kom qhuav. Kom qhuav yog tiav los ntawm kev siv a desiccant los yog tshuab ziab khaub ncaws ua ntej tus tsiaj PET tau pub rau hauv cov cuab yeej siv ua khoom lag luam.

Sab hauv lub tshuab ziab khaub ncaws, huab cua kub qhuav yog nqus rau hauv qab ntawm lub plhaw uas muaj cov dej kom nws ntws mus los ntawm lub pellets, tshem tawm ya raws ntawm nws txoj kev. Cov huab cua sov ntub tawm ntawm lub plhaw sab saum toj thiab thawj zaug khiav los ntawm lub sijhawm tom qab txias dua, vim tias nws yooj yim tshem tawm ya raws los ntawm huab cua txias dua li huab cua kub. Qhov tshwm sim txias huab cua txias yog tom qab ntawd dhau los ntawm ib lub txaj desiccant. Thaum kawg, qhov cua txias qhuav tawm hauv lub txaj desiccant tau rov ua dua hauv cov txheej txheem rhaub thiab xa rov qab los ntawm cov txheej txheem zoo ib yam hauv lub voj kaw. Feem ntau, cov dej noo cov dej noo ntau ntau hauv cov dej yuav tsum tsis pub tsawg tshaj 50 feem hauv ib lab (qhov dej ntawm ib lab ntawm cov dej, los ntawm qhov hnyav) ua ntej kev ua. Lub sijhawm ziab tsev nyob yuav tsum tsis txhob luv dua li plaub teev. Qhov no yog vim tias ziab cov khoom hauv tsawg dua 4 teev yuav xav tau kub siab tshaj 160 ° C, nyob rau theem twg hydrolysis yuav pib hauv cov pellets ua ntej lawv yuav ua kom qhuav.

Cov tsiaj kuj tseem tuaj yeem qhuav hauv compressed cua cob tshuab. Cov cua tshuab zaws tsis txhob rov qab siv lub tshuab cua kom qhuav. Qhuav, rhuab compressed cua yog circulated los ntawm PET pellets xws li hauv tshuab kom qhuav, tom qab ntawd tso tawm rau qhov chaw.

Tshuab Luam Ntawv

Ntxiv rau qhov ntshiab (homopolymer) PET, tus tsiaj hloov los ntawm copolymerization kuj muaj.

Muaj qee kis, cov khoom raug hloov kho ntawm copolymer yog qhov tsim nyog dua rau ib daim ntawv thov tshwj xeeb. Piv txwv li, Cyclohexane dimethanol (CHDM) tuaj yeem raug ntxiv rau polymer pob txha caj qaum ethylene glycol hmoovCov. Txij li thaum lub tsev thaiv no yog ntau dua (6 ntxiv carbon atoms) dua li cov ethylene glycol chav nws hloov, nws tsis haum rau nrog cov hlua sib txuas ib puag ncig ntawm txoj kev ib qho kev sib koom ua ke ethylene glycol. Qhov no cuam tshuam nrog crystallization thiab qis qis dua polymer lub siab kub. Feem ntau, xws li PET yog lub npe hu ua PETG lossis PET-G (Polyethylene terephthalate glycol-hloov kho; Eastman Tshuaj, SK Tshuaj, thiab Artenius Italia yog qee cov PETG manufacturers). PETG yog tus ntshiab amorphous thermoplastic uas tuaj yeem raug txhaj tshuaj moulded lossis daim ntawv extruded. Nws tuaj yeem yog xim thaum lub sijhawm ua haujlwm.

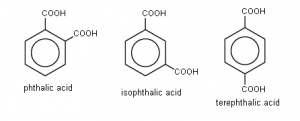

Lwm qhov hloov kho yog isophthalic acid, hloov qee yam ntawm 1,4- (kev) sib txuas terephthalate chav nyob. Lub 1,2- (ortho-) lossis 1,3- (lub hom phiaj-) kev sib txuas ua rau lub kaum ntse ntse nyob hauv cov saw, uas kuj cuam tshuam rau cov neeg sab nraud.

Xws li cov tshuab luam ntawv tau zoo rau qee qhov kev siv tshuaj molding, xws li thermoforming, uas yog siv piv txwv li ua lub tais los yog cov hlwv ntim los ntawm co-PET zaj duab xis, lossis amorphous PET ntawv (A-PET) lossis PETG ntawv. Ntawm qhov tod tes, crystallization yog qhov tseem ceeb hauv lwm daim ntawv thov qhov twg kev siv tshuab thiab qhov ntev seem yog qhov tseem ceeb, xws li siv txoj siv sia. Rau cov tsiaj fwj, cov tshuaj siv me me ntawm isophthalic acid, CHDM, diethylene glycol cov (DEG) lossis lwm tus tsim nyog tuaj yeem muaj txiaj ntsig: yog tias tsuas yog siv hluav taws xob me me xwb, kev siv lead ua qeeb qeeb tab sis tsis tiv thaiv nkaus. Raws li qhov tshwm sim, fwj tau tsim los ntawm ncab tshuab moulding ("SBM"), uas yog ob qho tib si meej thiab ci ntsa iab txaus los ua ib qho laj kab txaus rau cov pa tsw qab thiab txawm muaj roj, xws li carbon dioxide nyob rau hauv cov dej haus.

Qhuav

Polyethylene terephthalate yog tsim los ntawm ethylene glycol hmoov thiab Dimethyl terephthalate hmoov (C6H4(CO2CH3)2) los yog terephthalic kua qaub.

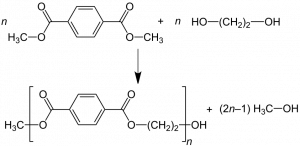

Tus qub yog a transesterification cov tshuaj tiv thaiv, whereas qhov kawg yog ib qho esterification kev tawm tsam.

Dimethyl terephthalate txheej txheem

In Dimethyl terephthalate hmoov cov txheej txheem, no compound thiab tshaj ethylene glycol yog hnov mob hauv yaj ntawm 150-200 ° C nrog a pib catalyst. methanol (CH3OH) raug muab tshem tawm los ntawm distillation los tsav qhov tshuaj tiv thaiv rau pem hauv ntej. Tshaj li ntawm ethylene glycol yog distilled tawm ntawm qhov kub siab tshaj nrog kev pab ntawm nqus tsev. Qhov thib ob transesterification qib tau nyaij ntawm 270-280 ° C, nrog kev txuas ntxiv distillation ntawm ethylene glycol zoo li.

Cov kev tawm tsam yog cov qauv zoo xws li nram no:

- Thawj kauj ruam

- C6H4(CO2CH3)2 + 2 HOCHIM2CH2OH → C.6H4(CO2CH2CH2OH)2 + 2 CH UA3OH

- Kauj ruam ob

- n C6H4(CO2CH2CH2OH)2 → [(CO) C6H4(CO2CH2CH2Yog)]n + n HOCH2CH2OH

Terephthalic acid txheej txheem

Nyob rau hauv lub terephthalic kua qaub cov txheej txheem, esterification ntawm ethylene glycol thiab terephthalic acid yog ua ncaj qha ntawm kev kub ceev (2.7-5.5 bar) thiab qhov kub thiab txias (220-260 ° C). Dej yog tshem tawm hauv qhov tshuaj tiv thaiv, thiab nws tseem yog txuas ntxiv tshem tawm los ntawm distillation:

- n C6H4(CO2H)2 + n HOCH2CH2OH → [(CO) C6H4(CO2CH2CH2Yog)]n + 2n H2O

degradation

PET raug rau ntau yam kev hloov pauv thaum lub sijhawm ua haujlwm. Cov kev mob loj uas tuaj yeem tshwm sim yog hydrolytic, thiab tej zaum tseem ceeb tshaj, thermal oxidation. Thaum PET degrades, ntau yam tshwm sim: raug tshem tawm, saw tshem tawm ua rau txo molecular phaus, tsim ntawm acetaldehyde, Thiab txuas txuas ("Gel" lossis "ntses qhov muag" tsim). Kev tshem tawm yog vim muaj ntau yam kev tsim cov tshuab chromophoric tom qab kev kho cua sov ntev ntawm qhov kub nce. Qhov no dhau los ua teeb meem thaum qhov kev xav tau qhov zoo ntawm cov polymer yog qhov ntau heev, xws li hauv cov ntawv thov ntim. Lub thermal thiab thermooxidative kev ua haujlwm tsis zoo ua rau cov txheej txheem tsis zoo cov txheej txheem thiab kev ua tiav ntawm cov khoom.

Ib txoj hauv kev los daws qhov no yog siv a copolymerCov. Cov neeg sawv cev xws li CHDM lossis isophthalic acid qis dua qhov kub siab melting thiab txo qhov kub ntawm crystallinity ntawm PET (tshwj xeeb tshaj yog tseem ceeb thaum cov khoom siv rau lub raj mis tsim). Yog li, cov nplaum yuav ua tau plastically ntawm qhov kub qis thiab / lossis nrog lub zog quab yuam. Qhov no pab tiv thaiv kom tsis txhob muaj qhov tsis zoo, txo cov ntsiab lus acetaldehyde ntawm cov khoom tiav rau qhov kev lees txais (uas yog, tsis paub txog qib). Saib copolymer, saum toj no. Lwm txoj kev los txhim kho kev ruaj ntseg ntawm cov polymer yog siv cov tshuaj stabilizers, feem ntau cov tshuaj tiv thaiv antioxidant xws li cov phosphitesCov. Tsis ntev los no, cov qib theem kev ruaj ntseg ntawm cov khoom siv cov tshuaj nanostructured kuj tau txiav txim siab.

Acetaldehyde

Acetaldehyde yog qhov tsis muaj kob, muaj lub cev nrog cov ntxhiab tsw. Txawm hais tias nws tsim nyob rau hauv ib co txiv hmab txiv ntoo, nws yuav ua rau tawm ntawm saj hauv dej fwj. Cov ntaub ntawv Acetaldehyde los ntawm kev ua tsis zoo ntawm PET los ntawm kev tsis ncaj ncees ntawm cov khoom. Kev kub muaj peev txheej (PET decomposes siab tshaj 300 ° C lossis 570 ° F), siab pressures, extruder siab (ntau dhau ntawm shear txaus ua rau muaj qhov kub thiab txias), thiab lub thoob ntev nyob rau txhua lub sijhawm ua rau muaj kev tsim cov acetaldehyde. Thaum cov tshuaj acetaldehyde tsim tawm, qee qhov nws nws qee yam yog yaj ntawm phab ntsa ntawm lub thawv ntim thiab tom qab ntawd diffuse rau hauv cov khoom khaws cia sab hauv, hloov cov saj thiab tsw qab. Qhov no tsis yog teeb meem rau cov tsis haus (xws li tshuaj zawv plaub hau), rau cov kua txiv (uas twb muaj acetaldehyde), lossis rau cov dej qab muaj zog haus xws li dej haus. Rau cov dej hauv hwj, txawm li cas los xij, cov ntsiab lus tsis tshua muaj acetaldehyde yog qhov tseem ceeb heev, vim tias, yog tias tsis muaj dab tsi npog lub aroma, txawm tias qhov tsis tshua muaj neeg ntau ntau (10-20 qhov twg ib lab hauv dej) ntawm acetaldehyde tuaj yeem tsim cov khoom tawm.

antimony

antimony (Sb) yog qhov sib txawv hu ua metalloid uas yog siv los ua lub hauv paus hauv kev sib txuas hauv cov ntawv sib txuas xws li antimony trioxide cov (Sib2O3) lossis antimony triacetate hauv kev tsim cov tsiaj PET. Tom qab tsim khoom, cov nyiaj tuaj yeem tiv thaiv cov pa tuaj yeem nrhiav tau ntawm cov khoom lag luam. Cov khoom seem no tuaj yeem muab tshem tawm nrog kev ntxhua. Antimony tseem nyob hauv cov khoom nws tus kheej thiab tuaj yeem, yog li, tsiv tawm mus rau hauv cov zaub mov thiab dej haus. Kev tawm ntawm PET mus rau lub rwj lossis microwaving tuaj yeem ua rau kom muaj ntau yam kev ua kom muaj antimony zoo, tejzaum nws siab dua USEPA qib siab tshaj plaws. Cov dej tsis pub haus tshaj kev soj ntsuam los ntawm WHO yog 20 feem rau ib billion (WHO, 2003), thiab cov dej haus txwv hauv Tebchaws Asmeskas yog 6 feem hauv ib lab. Txawm hais tias antimony trioxide yog qhov muaj tshuaj lom tsawg thaum noj ntawm qhov ncauj, nws lub xub ntiag tseem muaj kev txhawj xeeb. Lub Swiss Tsoomfwv Chaw Haujlwm Saib Xyuas Kev Noj Qab Haus Huv tshawb xyuas cov nyiaj ntawm cov neeg ua haujlwm antimony ntau dua, sib piv cov dej hauv lub taub tsiaj hauv PET thiab iav: Qhov antimony ntau ntawm cov dej hauv PET lub raj muaj ntau dua, tab sis tseem nyob qis dua qhov kev tso cai siab tshaj. Tsoomfwv Meskas Lub Chaw Haujlwm Saib Xyuas Kev Noj Qab Haus Huv Kev Noj Qab Haus Huv xaus lus tias me me ntawm kev ua yeeb yam tsiv tawm ntawm PET mus rau hauv lub taub dej, tab sis tias kev noj qab haus huv muaj kev pheej hmoo ua rau muaj kev tsis txaus ntseeg yog qhov tsis lees paub (1% ntawm "tiv taus txhua hnub”Txiav txim los ntawm tus LEEJ TWG)). Ib qho tom qab (2006) tab sis qhov kev tshawb fawb pom ntau tau pom muaj qhov sib npaug ntawm cov dej hauv cov dej hauv cov tsiaj fwj. Lub koom haum WHO tau tshaj tawm txoj kev pheej hmoo txhawm rau haus luam yeeb hauv dej haus.

Cov kua txiv ntoo ua kua concentrates (rau cov uas tsis muaj cov lus qhia tau tsim), txawm li cas los xij, uas tau tsim thiab ntim hauv cov tsiaj hauv PET hauv tebchaws Askiv tau pom tias muaj txog 44.7 µg / L ntawm kev ua yeeb yam, zoo dua li EU txwv rau siv dej ntawm 5 µg / L.

Kev hloov kho biode

Nocardia tuaj yeem thuam PET nrog qhov esterase enzyme.

Cov kws tshawb fawb hauv Japanese tau cais tus kab mob Ideonella sakaiensis uas muaj ob lub enzymes uas tuaj yeem zom PET rau hauv me me uas cov kab mob tuaj yeem zom tawm. Ib pawg ntawm I. sakaiensis tuaj yeem sib cais hauv cov yeeb yaj kiab yas hauv li ntawm rau lub lis piam.

Kev Nyab Xeeb

Kev tawm tswv yim tshaj tawm hauv Environmental Perspectives lub Plaub Hlis 2010 tau hais tias PET yuav tuaj yeem tawm los kev cuam tshuam dab tsi endocrine nyob rau hauv cov xwm txheej ntawm kev siv ntau thiab pom zoo tshawb fawb txog cov ncauj lus no. Cov ncauj lus tawm tswv yim suav nrog kev laij ntawm phthalates zoo li yog leaching ntawm antimonyCov. Ntawv xov xwm luam tawm hauv Phau ntawv Journal ntawm kev soj ntsuam ib puag ncig nyob rau lub Plaub Hlis 2012 xaus lus tias antimony concentration hauv deionized dej khaws cia rau hauv cov tsiaj hwj nyob hauv EU qhov txwv txaus txawm tias yuav khaws cia luv nyob rau qhov kub txog 60 ° C (140 ° F), thaum lub fwj dej haus (dej los yog dej haus) yuav qee zaum tshaj qhov EU txwv nyob tom qab tsawg dua ib xyoos ntawm kev khaws cia hauv chav kub.

Cov khoom siv txau ntim khoom

Muaj ob txoj hauv kev txhaj tshuaj molding rau cov tsiaj PET, ib-kauj ruam thiab ob-kauj ruam. Hauv ob-kauj ruam moulding, ob cais cov tshuab siv. Thawj lub tshuab txhaj tshuaj moulds lub preform, uas zoo li lub xeem ntsuas, nrog lub raj mis-xov xov twb molded rau hauv qhov chaw. Lub cev ua haujlwm ntawm lub raj yog qhov ua kom tuab, thaum nws yuav ua kom nrawm mus rau hauv nws cov duab kawg hauv theem ob siv ncab tshuab moulding.

Hauv kauj ruam thib ob, cov qauv uas tau tshaj tawm yog ua kom sov sai thiab tom qab ntawd ua kom nruj tiv thaiv ob ntu pwm los ua lawv rau hauv qhov kawg ntawm lub hwj. Preforms (cov tshuab fwj tsis ntim) tam sim no kuj tseem siv los ua cov thawv muaj zog thiab ntim khoom rau lawv tus kheej; dua li cov khoom qab zib tshiab, qee tshooj hauv Red Cross faib lawv ua ib feem ntawm Vial ntawm lub neej txoj haujlwm rau cov tswv tsev khaws cov keeb kwm kho mob rau cov neeg teb. Lwm qhov kev siv ntau dua rau cov qauv no yog ntim hauv cov haujlwm sab nraum zoov Geocaching.

Hauv ib-kauj ruam tshuab, tag nrho cov txheej txheem los ntawm cov khoom siv raw mus rau lub thawv tiav yog ua nyob rau hauv ib lub tshuab, ua rau nws tshwj xeeb tshaj yog tsim rau moulding tsis txheem txheej (kev cai moulding), suav nrog cov rhawv, tiaj tus kheej kheej, flask cov duab thiab lwm yam. qhov kev txo tawm hauv qhov chaw, kev tswj cov khoom lag luam thiab lub zog, thiab qhov pom tau zoo dua li qhov ua tau los ntawm ob-kauj ruam system.

Polyester kev lag luam ub khoom lag luam

Hauv xyoo 2016, tau kwv yees tias 56 lab tons ntawm PET tsim txhua xyoo.

Thaum feem ntau cov thermoplastics tuaj yeem, hauv paus ntsiab lus, tau rov ua dua, Tus tsiaj lub raj mis rov ua dua tshiab yog qhov tswv yim ntau dua li lwm cov ntawv yas vim tias cov txiaj ntsig siab ntawm kev siv roj hmab thiab yuav luag siv PET rau kev siv dej thiab cov pa roj carbon ntau rau hauv lub raj mis. Tsiaj muaj ib cob qhia cov lej cim ntawm 1. Thawj tus siv rau kev rov siv dua tus tsiaj yog polyester fiber, strapping, thiab cov thawv ntim khoom noj.

Vim hais tias ntawm recyclability ntawm PET thiab tus txheeb ze nplua nuj ntawm cov neeg siv khoom pov tseg tom qab nyob rau hauv daim ntawv ntawm lub hwj, PET tau sai sai rau kev ua lag luam raws li cov ntaub pua plag fiber ntau. Mohawk Kev Lag Luam tawm puas dhau los hauv lub xyoo 1999, 100% cov neeg siv khoom xa rov qab cov ntsiab lus PET fiber. Txij lub sijhawm ntawd, ntau tshaj 17 billion lub fwj dej tau rov ua dua rau hauv cov ntaub pua plag ntaub pua tsev. Pharr Yarns, tus neeg xa khoom rau ntau cov ntaub pua plag tuam txhab suav nrog Looptex, Dobbs Mills, thiab Berkshire Flooring, tsim cov khoom siv BCF (cov kab nruam txuas ntxiv) PET cov ntaub pua plag fiber ntau uas muaj qhov tsawg kawg 25% cov neeg siv khoom siv rov qab.

PET, ib yam li nrog ntau plastics, kuj yog tus neeg sib tw zoo rau kev pov tseg thermal (hlawv), raws li nws yog li ntawm carbon, hydrogen, thiab oxygen, nrog tsuas yog kab ntawm catalyst cov ntsiab lus (tab sis tsis muaj leej faj). PET muaj lub zog cov ntsiab lus ntawm cov mos mos.

Thaum rov ua dua tshiab polyethylene terephthalate lossis PET lossis polyester, feem ntau ob txoj hauv kev yuav tsum muaj qhov sib txawv:

- Cov tshuaj thim rov qab siv cov tshuaj rov qab mus rau qhov pib cov khoom nyoos lim terephthalic kua qaub (PTA) lossis Dimethyl terephthalate hmoov (DMT) thiab ethylene glycol hmoov (EG) qhov twg cov qauv polymer puas tsuaj pov tseg tag nrho, lossis hauv cov txheej txheem intermediates nyiam bis (2-hydroxyethyl) terephthalate

- Cov neeg kho tshuab rov ua qhov chaw uas cov khoom qub polymer tau raug tswj los yog rov ua dua tshiab.

Kev ua tshuaj lom cov tshuaj ntawm PET yuav dhau los ua tus nqi tsuas yog thov cov peev txheej muaj peev txheej rov qab ntau dua 50,000 tons / xyoo. Cov kab no tsuas yog pom, yog tias txhua lub sijhawm, hauv thaj chaw tsim khoom ntawm cov neeg tsim cov tshuab hluav taws xob polyester. Ob peb qhov kev cia siab ntawm kev lag luam ntau los tsim cov tshuaj ub tsob no tau siv yav dhau los tab sis tsis muaj qhov ua tiav. Txawm tias muaj kev cog lus tshuaj lom neeg tshiab hauv Nyij Pooj tsis tau dhau los ua kev lag luam kev lag luam. Qhov ob qho laj thawj rau qhov no yog: thaum xub thawj, qhov nyuaj ntawm cov khoom sib txig sib luag thiab tsis tu ncua ntawm cov khoom ntim rau qhov muaj peev txheej ntau ntawm ib qho chaw, thiab, qhov thib ob, tus nqi tsis hloov zuj zus thiab tus nqi hloov pauv ntawm cov fwj. Tus nqi ntawm cov hwj tau ntim ntau ntxiv piv txwv li ntawm xyoo 2000 txog 2008 txij li ntawm 50 Euro / nyhav ib toos mus txog 500 Euro / tuj hauv 2008.

Kev kho tshuab rov qab lossis rov ncig ncaj qha ntawm PET hauv lub xeev polymeric ua haujlwm hauv kev sib txawv ntawm cov khoom siv niaj hnub no. Cov txheej txheem zoo li no yog kev lag luam me thiab nruab nrab. Kev siv nyiaj-tau siv txiaj ntsig tuaj yeem ua tiav nrog cov peev txheej cog hauv thaj tsam li ntawm 5000-20,000 tons / xyoo. Hauv qhov xwm txheej no, yuav luag txhua yam ntawm cov khoom siv rov ua dua tshiab los hloov cov lus pom rau hauv cov khoom siv khoom tsim muaj niaj hnub no. Cov txheej txheem ub no coj los sib tham ua ntu zus tom qab no.

Dhau li ntawm cov kuab tshuaj lom thiab degradation cov khoom lag luam tsim thaum ua thawj zaug thiab kev siv, cov tshuab ua kom lub cev tsis zoo yog sawv cev ntawm feem tseem ceeb ntawm kev txo nqi tsis txaus nyob rau hauv cov dej rov ua dua tshiab. Cov khoom siv rov ua dua tshiab tau nce zuj zus mus rau hauv kev tsim cov txheej txheem, uas tau xub tsim los rau cov ntaub ntawv tshiab nkaus xwb. Yog li no, kev xaiv zoo, kev sib cais thiab tu cov txheej txheem ua qhov tseem ceeb tshaj plaws rau cov khoom siv ua dua tshiab polyester.

Thaum tham txog kev lag luam polyester rov ua dua tshiab, peb tau tsom ntsoov rau kev rov ua dua tshiab ntawm cov tsiaj raj mis PET, uas yog lub sijhawm no siv rau txhua yam kev ntim kua xws li dej, dej haus, kua txiv, npias, kua ntses, tshuaj ntxuav tsev, tshuaj ntxuav tsev thiab lwm yam. Cov taub tau yooj yim rau kev sib txawv vim muaj cov qauv thiab sib thooj thiab sib cais los ntawm cov khib nyiab yas ntws los ntawm kev siv tshuab lossis txheej txheem ua haujlwm. Lub chaw tsim khoom lag luam polyester rov ua dua tshiab muaj peb ntu loj:

- Cov tsiaj lub raj mis sau thiab cov khib nyiab sib cais: khib nyiab logistics

- Kev tsim cov raj mis huv: plaub hau flake

- Kev hloov pauv ntawm cov tsiaj plaub ya ri mus rau cov khoom kawg: kev ua tiav

Cov khoom lag luam theem nrab ntawm ntu ntu yog cov khoom qab zib lub raj mis nrog cov ntsiab lus PET ntau dua 90%. Feem ntau hom kev ua lag luam yog lub bale tab sis kuj bricked lossis txawm tias xoob, lub raj mis ua ntej txiav tau ntau nyob rau hauv kev ua lag luam. Hauv seem thib ob, tus cug quav tau muab pauv rau kev ntxuav tsiaj PET lub raj mis flakes. Cov kauj ruam no tuaj yeem ua ntau dua lossis ntau dua thiab muaj ntau ntxiv nyob ntawm seb yuav ua dab tsi flake zoo kawg nkaus. Thaum lub sijhawm peb kauj ruam, PET lub raj mis plaub ya yog ua tiav rau txhua yam khoom lag luam xws li zaj duab xis, lub raj mis, fiber ntau, lim pom, pluaj lossis cuam tshuam xws li pellets rau kev ua cov txheej txheem txuas ntxiv thiab engineering plastics.

Dhau li ntawm qhov sab nraud (tom qab tus neeg siv khoom) cov raj mis polyester rov ua dua tshiab, cov lej ntawm sab hauv (cov neeg siv khoom ua ntej) cov txheej txheem rov ua dua tshiab, qhov twg cov khoom siv pov tseg tsis muaj qhov tawm ntawm qhov chaw tsim khoom mus rau lub lag luam dawb, thiab hloov dua tshiab siv rau hauv kev tsim hluav taws xob. Nyob rau hauv txoj kev no, cov pov tseg fiber ntau yog ncaj qha rov siv dua los ua cov tshuaj fiber, cov khib nyiab preform yog ncaj qha rov siv dua los tsim cov preforms, thiab cov pov tseg zaj duab xis yog rov siv ncaj qha los tsim zaj duab xis.

Tus tsiaj lub raj mis rov ua dua tshiab

Kev ua kom huv huv thiab kev tshem tawm

Kev ua tiav ntawm txhua lub tswv yim ua kom rov qab tau muab zais rau hauv kev ua haujlwm ntawm kev ua kom huv thiab tshem tawm qhov chaw nyob rau qhov chaw thaum lub sijhawm ua thiab rau qhov tsim nyog lossis xav tau.

Hauv qhov dav dav, cov hauv qab no siv: Cov ua ntej hauv cov txheej txheem cov tshuaj txawv teb chaws raug muab tshem tawm, thiab ntau qhov kev ua kom tiav qhov no yog ua tiav, cov txheej txheem zoo dua.

Lub siab Yas qhov kub ntawm PET nyob rau hauv thaj tsam ntawm 280 ° C (536 ° F) yog qhov laj thawj vim li cas yuav luag txhua qhov feem ntau organic impurities xws li PVC, PLA, polyolefin, tshuaj ntoo-pulp thiab ntawv fiber ntau, polyvinyl acetate hmoov, yaj nplaum, cov kab mob pleev xim, qab zib, thiab protein cov seem uas tau hloov mus rau cov khoom lag luam degradation uas, nyob rau hauv lawv lem, yuav tso ntxiv rau cov khoom tiv thaiv kev tiv thaiv tsis zoo. Tom qab ntawd, tus naj npawb ntawm cov tsis xws luag hauv cov saw polymer nce siab zoo. Qhov loj me faib tawm ntawm impurities yog qhov dav heev, qhov loj me ntawm 60–1000 µm - uas pom los ntawm lub qhov muag liab qab thiab yooj yim rau lim - sawv cev rau qhov tsis zoo dua, vim lawv qhov chaw tag nrho me me thiab qhov ceev ceev yog li qis. Kev cuam tshuam ntawm cov ntawv me me, uas - vim tias lawv muaj ntau - ua kom ntau zaus ntawm qhov tsis xws ntawm qhov tsis xws luag, yog qhov ntau dua.

Cov lus "Lub ntsiab uas lub qhov muag tsis pom lub siab tuaj yeem tsis tu siab" yog qhov tseem ceeb rau ntau qhov kev ua rov ua dua tshiab. Yog li ntawd, dhau li ntawm kev xaiv kom muaj txiaj ntsig, qhov kev tshem tawm ntawm qhov pom pom tsis muaj zog los ntawm kev pom kev pom los ntawm cov txheej txheem sib xyaw ua si ib feem tshwj xeeb ntawm qhov no.

Feem ntau, ib tus tuaj yeem hais tias cov txheej txheem los ua kom PET lub raj mis flakes los ntawm cov fwj ntim tau ntim tau zoo ib yam li cov khib nyiab sib txawv muaj qhov sib txawv hauv lawv cov muaj pes tsawg leeg thiab qhov ua tau zoo. Hauv kev pom ntawm thev naus laus zis tsis muaj ib txoj hauv kev los ua nws. Lub caij no, muaj ntau lub tuam txhab ua haujlwm tsim khoom tshuab tshuab flake ntau lawm thiab cov khoom sib xyaw, thiab nws nyuaj rau kev txiav txim siab rau ib lossis lwm cov qauv ntoo. Txawm li cas los xij, muaj txheej txheem uas tau sib koom nrog feem ntau ntawm cov hauv paus ntsiab lus no. Ua raws li muaj pes tsawg leeg thiab kev ua tsis ncaj ntawm cov khoom nkag, cov kev coj ua hauv qab cov txheej txheem tau ua.

- Bale qhib, pob zeb ci qhib

- Txheeb xyuas thiab xaiv cov xim sib txawv, cov duab tso cai txawv teb chaws tshwj xeeb tshaj yog PVC, teeb meem txawv teb chaws, tshem tawm zaj duab xis, ntawv, iav, xuab zeb, av, pob zeb, thiab hlau

- Ua ntej ntxuav tsis tas txiav

- Ntxhib txiav qhuav los yog ua ke kom ntxuav ua ntej

- Kev tshem tawm cov pob zeb, iav, thiab hlau

- Huab cua sifting tshem zaj duab xis, ntawv, thiab cov ntawv cim

- Sib tsoo, qhuav thiab / lossis ntub

- Tshem tawm ntawm cov qes polymer (khob) los ntawm cov khoom siv sib txawv

- Kub-ntxuav

- Caustic ntxuav, thiab txheej etching, tswj kev ua haujlwm khov viscosity thiab ua kom paug

- Rinsing

- Dej huv yaug

- Kom qhuav

- Huab cua-sifting ntawm plaub ya ri

- Tsis siv neeg flake sorting

- Dej Circuit Court thiab kev siv tshuab kho dej

- Flake zoo tswj

Qhov tsis zoo thiab cov khoom tsis xws

Tus naj npawb ntawm cov khoom tsis zoo thiab cov khoom siv tsis zoo uas nthuav tawm hauv cov khoom siv polymeric yog nce ntxiv mus tas li - thaum kev ua cov txheej txheem thiab thaum siv cov tshuaj polymers - suav txog kev pabcuam kev ua neej nyob, kev siv cov ntawv thov kawg thiab rov ua dua tshiab. Raws li rov qab ua PET lub raj mis muaj kev txhawj xeeb, qhov tsis xws li tau tuaj yeem txheeb raws cov pawg hauv qab no:

- Polyester rov qab ua si OH- lossis COOH- pawg kawg tau hloov pauv mus ua cov pab pawg tuag lossis tsis tshua muaj siab, piv txwv li tsim cov vinyl ester kawg pawg los ntawm lub cev qhuav dej lossis decarboxylation ntawm terephthalate acid, cov tshuaj tiv thaiv ntawm OH- lossis COOH- kawg pab pawg nrog mono-ua haujlwm kev ua rau cov khoom lag luam zoo li mono-carbonic acids lossis dej cawv. Cov txiaj ntsig yog qhov tsis tshua hno thaum lub sijhawm rov ua haujlwm polycondensation lossis rov ua haujlwm SSP thiab nthuav dav cov kev faib tawm molecular.

- Cov pab pawg kawg kawg hloov mus rau kev coj ntawm COOH kawg pawg ua los ntawm kev thermal thiab oxidative degradation. Cov txiaj ntsig tau txo qis hauv kev ua haujlwm, thiab nce ntxiv hauv cov kua qaub autocatalytic decomposition thaum kho cua sov nyob rau hauv muaj cov av noo.

- Tus naj npawb ntawm polyfunctional macromolecules nce. Kev nkag mus ntawm cov gels thiab ntev-cov saw txhim kho cov teeb meem.

- Tus naj npawb, kev cia siab, thiab ntau yam ntawm nonpolymer-zoo ib yam li cov organic thiab cov tshuaj lom neeg txawv teb chaws tau nce zuj zus. Nrog txhua cov kev kub ntxhov tshiab hauv kev ntxhov siab, cov tshuaj organic txawv teb chaws yuav hnov mob los ntawm kev ua kom zoo. Qhov no yog qhov ua kom muaj kev tso tawm ntawm kev tiv thaiv ntxiv kev xiam oob qhab thiab cov xim yeeb tshuaj.

- Hydroxide thiab peroxide pawg teeb tsa nyob saum npoo ntawm cov khoom ua los ntawm polyester nyob ntawm huab cua (oxygen) thiab av noo. Cov txheej txheem no tau nrawm dua los ntawm ultraviolet lub teeb. Thaum ua cov txheej txheem kho mob ulterior, hydro peroxides yog qhov ntawm oxygen radicals, uas yog qhov chaw ntawm oxidative degradation. Kev rhuav tshem ntawm hydro peroxides yog tshwm sim ua ntej kev kho cua sov thawj zaug lossis thaum hloov kho hluav taws xob thiab tuaj yeem txhawb los ntawm cov khoom sib ntxiv zoo li antioxidants.

Coj mus rau hauv kev txiav txim siab cov tshuaj uas hais los saum toj no thiab qhov tsis zoo, muaj qhov hloov kho tsis tu ncua ntawm cov yam ntxwv polymer hauv qab no txhua lub hlis rov ua dua, uas pom tau los ntawm tshuaj lom neeg thiab tshuaj ntsuam lub cev tsom.

Hauv particular:

- Nce ntawm COOH kawg-pab pawg

- Nce ntawm cov xim tooj b

- Nce ntawm haze (cov khoom pob tshab)

- Nce ntawm oligomer cov ntsiab lus

- Kev txo qis hauv kev ua qias neeg

- Ua kom muaj cov ntsiab lus xws li acetaldehyde, formaldehyde

- Nce ntawm cov khoom siv txawv teb chaws kis tau

- Txo cov xim L

- Txo ntawm intrinsic viscosity lossis dynamic viscosity

- Kev txo qis ntawm crystallization kub thiab nce ntawm crystallization ceev

- Txo cov neeg kho tshuab zog xws li lub zog tensile, elongation thaum tawg lossis elastic qauv

- Kev nthuav dav ntawm cov khoom lag luam hnyav molecular

Kev rov ua dua tshiab ntawm PET-lub raj mis yog lub sijhawm no tus txheej txheem kev lag luam uas tau muab los ntawm ntau cov tuam txhab engineering.

Ua cov piv txwv rau cov khoom siv rov ua dua tshiab polyester

Cov txheej txheem thim cov khoom siv nrog polyester yog yuav luag txhua yam li cov txheej txheem tsim tawm los ntawm cov thawj pellets lossis yaj. Ua raws li kev coj dawb huv ntawm cov khoom siv rov ua dua tshiab, polyester tuaj yeem siv niaj hnub no nyob rau hauv feem ntau ntawm cov khoom siv hluav taws xob polyester ua cov sib xyaw nrog nkauj xwb polymer lossis nce li 100% cov khoom siv rov ua dua tshiab. Qee qhov tshwj xeeb xws li BOPET-zaj duab xis ntawm cov tuab tuab tsawg, cov ntawv thov tshwj xeeb zoo li zaj duab xis kho qhov muag los yog yarns los ntawm FDY-spinning ntawm> 6000 m / min, microfilaments, thiab micro-fibers yog tsim los ntawm nkauj xwb polyester.

Yooj yim re-pelletizing ntawm flakes fwj

Cov txheej txheem no muaj kev hloov pauv cov raj mis pov tseg mus rau hauv plaub ya ri, los ntawm kev ziab thiab crystallizing plaub ya ri, los ntawm plasticizing thiab lim, zoo li los ntawm pelletizing. Cov khoom lag luam yog amorphous re-granulate ntawm kev nkag siab viscosity nyob rau hauv thaj tsam ntawm 0.55–0.7 dℓ / g, nyob ntawm seb ua li cas kom tiav ua ntej ziab ntawm PET flakes tau ua tiav.

Cov yeeb yam tshwj xeeb yog: Acetaldehyde thiab oligomers muaj nyob hauv cov pellets hauv qib qis; lub viscosity yog txo qee qhov, cov pellets yog amorphous thiab yuav tsum tau tawg thiab qhuav ua ntej kev ua tiav.

Ua rau:

- A-TSIAJ zaj duab xis rau thermoforming

- Ntxiv rau tsiaj PET ntau lawm

- Tub Npis ntim zaj duab xis

- TSIAJ Lub raj mis resin los ntawm SSP

- Ntaub pua plag xov

- Siv tshuab yas

- Filaments

- Tsis-khaus

- Ntim khoom siv kab txaij

- Staple fiber.

Xaiv txoj kev rov ua haujlwm txhais tau tias muaj kev hloov pauv ntxiv uas yog, ntawm ib sab, kev siv zog thiab kev siv nyiaj, thiab ua rau kev ua kom thermal puas tsuaj. Ntawm lwm sab, pelletizing kauj ruam yog muab qhov zoo hauv qab no:

- Muab siab lim pom

- Nruab nrab tswjhwm zoo

- Kev hloov kho los ntawm cov quav

- Cov khoom xaiv thiab sib cais los ntawm cov khoom zoo

- Kev hloov pauv ntau ntxiv

- Kev tsim kho kom zoo.

Kev Tsim Cov PET-pellets lossis flakes rau lub raj mis (lub raj mis mus rau lub raj mis) thiab A-PET

Tus txheej txheem no, raws li txoj cai, zoo ib yam li cov uas tau piav saum toj no; txawm li cas los xij, cov pellets uas tsim tau ncaj qha (txuas ntxiv lossis txuas ntxiv) cov nplai tawg thiab tom qab ntawd ua rau cov khoom siv hluav taws xob polycondensation (SSP) nyob rau hauv cov raj zaws hluav taws xob lossis cov kav dej ntsug. Thaum lub sijhawm ua cov kauj ruam no, qhov sib txuam sib xyaw viscosity ntawm 0.80–0.085 dℓ / g raug tsim kho dua thiab, tib lub sijhawm, cov ntsiab lus acetaldehyde raug txo mus rau <1 ppm.

Qhov tseeb tias qee lub tshuab tsim khoom lag luam thiab cov tsim tsim kab hauv Tebchaws Europe thiab Asmeskas ua cov kev ywj pheej kom rov ua haujlwm ywj pheej, piv txwv li thiaj li hu ua lub raj mis-rau-fwj (B-2-B), xws li TSWV YIM, Starlings, URRC lossis BÜHLER, feem ntau npaj cov ntawv pov thawj ntawm "muaj sia" ntawm cov khoom seem xav tau thiab ntawm kev tshem tawm cov qauv paug raws li FDA thov cov kev sib tw sib tw, uas tsim nyog rau daim ntawv thov ntawm cov kho polyester hauv zaub mov teb. Dhau li ntawm txoj kev pom zoo no nws yog ib qho tseem ceeb tias txhua tus neeg siv ntawm cov txheej txheem yuav tsum tau soj ntsuam FDA-txwv tsis pub siv rau cov khoom nyoos tsim los ntawm nws tus kheej rau nws cov txheej txheem.

Kev hloov pauv ncaj qha ntawm cov raj mis flakes

Txhawm rau kom txuag tau tus nqi, nce ntau ntawm cov neeg siv khoom nruab nrab polyester zoo li spinning mills, strapping mills, los yog cov zaj duab xis cam mills ua haujlwm ntawm kev siv ncaj qha ntawm PET-flakes, los ntawm kev kho mob ntawm cov fwj, nrog rau kev tsim khoom kom nce zuj zus tus naj npawb ntawm polyester intermediates. Txog kev kho qhov tsim nyog viscosity, dhau li ntawm kev ua kom qhuav ntawm cov plaub ya ri, nws yog qhov tsim nyog los kuj tseem rov ua dua qhov viscosity los ntawm polycondensation hauv melt theem lossis solid-state polycondensation ntawm plaub ya ri. PET flake hloov dua siab tshiab tam sim no yog thov ntxaib ntsia hlau extruders, ntau qhov ntsia hlau extruders lossis tshuab ntau lub tshuab thiab sib nqus nqus dej kom tshem tawm cov dej noo thiab tsis txhob muaj flake ua ntej kom qhuav. Cov txheej txheem no tso cai rau kev hloov pauv ntawm cov tsiaj tsis muaj PET tsis muaj viscosity txo qis los ntawm hydrolysis.

Hais txog kev noj PET lub raj mis plaub ya ri, qhov tseem ceeb ntawm li ntawm 70% yog hloov mus rau cov nqaij thiab cov lim dej. Thaum siv cov khoom siv ncaj qha theem nrab xws li lub raj mis flakes hauv cov txheej txheem kiv, muaj ob peb txoj hauv kev ua kom tau txais.

Kev ua haujlwm ntawm lub cev nrawm nrawm nrawm rau kev tsim cov POY ib txwm xav tau ib lub viscosity ntawm 0.62–0.64 dℓ / g. Pib ntawm lub raj mis plaub ya ri, viscosity tuaj yeem tsim los ntawm qhov ntsuas ntawm ziab. Kev siv ntxiv ntawm TiO2 yog tsim nyog rau cov xov paj dull lossis semi dull. Txhawm rau tiv thaiv spinnerets, kev ua haujlwm ntawm cov yaj yaj yog, nyob rau hauv txhua rooj plaub yog tsim nyog. Txog rau lub sijhawm, tus POY ua los ntawm 100% rov qab polyester yog tsawg dua vim tias cov txheej txheem no yuav tsum muaj qhov siab huv ntawm spinning yaj. Yuav luag txhua lub sijhawm, kev sib xyaw ntawm nkauj xwb thiab rov ua dua tshiab yog siv los.

Staple fiber ntau spun nyob rau hauv qhov sib txuam viscosity ntau yam uas yog theej me ntsis qis dua thiab uas yuav tsum nyob nruab nrab ntawm 0.58 thiab 0.62 dℓ / g. Hauv qhov no, ib yam nkaus thiab, yuav tsum tau viscosity tuaj yeem hloov kho los ntawm kev ziab lossis lub tshuab nqus tsev hloov kho thaum lub tshuab nqus tsev extrusion. Rau kho cov viscosity, txawm li cas los xij, ib qho txuas ntxiv ntawm cov saw ntev hloov kho li ethylene glycol hmoov or diethylene glycol cov kuj tseem siv tau.

Kev sib tsoo tsis-woven - nyob hauv lub tiaj titer nplua rau cov ntawv siv rau textile thiab cov ntaub qhwv hnyav tsis yog ntaub ua cov khoom siv yooj yim, piv txwv li rau cov vov vov lossis hauv cov tsev ua ke - tuaj yeem tsim los ntawm cov taub flakes fwj. Lub viav vias ntsig rov ntxiv yog ntxiv nyob rau ntawm thaj tsam ntawm 0.58–0.65 dℓ / g.

Ib daim teb uas muaj cov paj laum ntxiv nyob qhov twg cov khoom siv rov siv dua yog kev tsim cov khoom lag luam siab ntim cov ntim khoom ntim, thiab monofilaments. Hauv ob qho xwm txheej, qhov pib ua cov khoom siv yog cov khoom siv rov qab ua dua uas muaj kev nkag siab ntau dua. High-thev taus ntev ntim cov hlua raws li zoo li monofilament yog tom qab tsim tsim hauv cov txheej txheem yaj roj yaj.

Kev rov qab rau cov monomers

Polyethylene terephthalate tuaj yeem depolymerized kom tau cov khoom pov thawj ntawm cov monomers. Tom qab ua kom huv, cov monomers tuaj yeem siv los npaj cov tshuaj tshiab polyethylene terephthalate. Tus ester bonds hauv polyethylene terephthalate tuaj yeem muab pov tseg los ntawm hydrolysis, lossis los ntawm transesterification. Cov kev hloov pauv tsuas yog thim rov qab ntawm cov tau siv nyob rau hauv ntau lawm.

Ib feem glycolysis

Ib feem glycolysis (transesterification nrog ethylene glycol) hloov cov polymer txhav mus ua cov oligomers luv luv uas tuaj yeem yaj tau ntawm qhov kub tsawg. Thaum tso txoj kev cuam tshuam ntawm cov impurities, cov oligomers tuaj yeem muab txau rov qab rau hauv cov txheej txheem ntau lawm rau kev ua kom polymerization.

Txoj haujlwm muaj nyob rau hauv pub 10-25% lub raj mis flakes thaum tswj kev ua tau zoo ntawm lub raj mis pellets uas tsim tawm ntawm kab. Lub hom phiaj no yog daws teeb meem los ntawm PET lub raj mis flakes - twb tau thaum lawv thawj cov khoom yas, uas tuaj yeem nqa hauv ib qho- lossis ntau tus ntsia hlau txuas ntxiv - mus rau qhov tseem ceeb viscosity ntawm txog 0.30 dℓ / g los ntawm kev ntxiv me me ntawm ethylene glycol thiab los ntawm kev cuam tshuam qis-viscosity yaj kwj mus rau kev ua kom zoo ncaj qha tom qab plasticization. Tsis tas li ntawd, ntsuas kub tau coj mus rau qhov kev txwv qis tshaj. Ntxiv rau, nrog txoj kev ua no, kev muaj peev xwm ua kom muaj tshuaj lom neeg cov dej hauv lub cev (hydro peroxides) yog qhov ua tau los ntawm kev ntxiv P-stabilizer ncaj qha thaum ua plasticizing. Kev rhuav tshem ntawm cov pawg hydro peroxide yog, nrog rau lwm cov txheej txheem, twb tau ua tiav thaum lub sijhawm kawg ntawm kev kho flake piv txwv los ntawm kev ntxiv H3PO3Cov. Ib feem glycolyzed thiab nplua cov khoom siv rov ua dua tshiab txuas ntxiv mus txuas ntxiv rau esterification lossis prepolycondensation reactor, cov koob tshuaj ntau npaum li cas ntawm cov khoom siv tau raug kho kom haum.

Tag nrho cov glycolysis, methanolysis, thiab hydrolysis

Kev kho cov hluav taws xob polyester dhau los ntawm tag nrho cov glycolysis mus rau tag nrho hloov cov polyester rau bis (2-hydroxyethyl) terephthalate (C6H4(CO2CH2CH2OH)2)). Qhov kev sib tov no yog lim los ntawm lub tshuab nqus tsev, thiab yog ib qho ntawm cov khoom nruab nrab siv hauv cov khoom tsim cov tshuab polyester. Cov tshuaj tiv thaiv koom nrog yog raws li nram no:

- [(CO) C6H4(CO2CH2CH2Yog)]n + n HOCH2CH2OH → ua n C6H4(CO2CH2CH2OH)2

Txoj kev rov qab siv dua tshiab no tau ua tiav ntawm ib qhov kev lag luam hauv Nyij Pooj raws li kev sim ntau lawm.

Zoo sib xws rau tag nrho cov glycolysis, methanolysis hloov lub polyester rau Dimethyl terephthalate hmoov, uas tuaj yeem lim tau thiab nqus nqus:

- [(CO) C6H4(CO2CH2CH2Yog)]n + 2n CH3OH → ua n C6H4(CO2CH3)2

Methanolysis tsuas yog tsis tshua muaj nyob hauv kev lag luam niaj hnub no vim tias polyester ntau lawm raws li dimethyl terephthalate tau poob qis heev, thiab ntau tus neeg dimethyl terephthalate tau ploj lawm.

Tsis tas li saum toj no, polyethylene terephthalate tuaj yeem raug hydrolyzed rau terephthalic acid thiab ethylene glycol hmoov nyob rau hauv qhov kub siab thiab siab. Cov txiaj ntsig ntawm cov roj ua kua terephthalic acid tuaj yeem ua kom huv huv rov tsim dua tshiab rau cov khoom haum rau rov polymerization:

- [(CO) C6H4(CO2CH2CH2Yog)]n + 2n H2O → → n C6H4(CO2H)2 + n HOCH2CH2OH

Qhov qauv no tsis tshwm sim tau ua lag luam tsis tau.